Solvit Korea offers a solution

that is different from the existing insulation.

that is different from the existing insulation.

Heater cover

Insulation cover for electric heaters such as

injection molding machines and extruders. The injection molding machine has many problems

due to the high temperature cylinder, and

the risk of safety accidents is high and improvement is indispensable.

injection molding machines and extruders. The injection molding machine has many problems

due to the high temperature cylinder, and

the risk of safety accidents is high and improvement is indispensable.

Applications

Application field

Injection machine, extruder

power plant

Shipbuilding field

Features

Features

ENERGY SAVING AND WORK EFFICIENCY INCREASE

- 30-50% reduction in heater power consumption

- The surface temperature of the heater is around 200℃ and the worksite temperature is 40℃ or higher in summer , reducing cooling costs and increasing work efficiency.

REDUCTION OF SAFETY ACCIDENTS AND PRODUCT DEFECT RATES

- Eliminates the risk of burns by contacting the surface of the heater

- Eliminates the risk of electric shock due to contact with high voltage terminal blocks

- Prevents an increase in the defect rate of the injection product due to the rapid cooling of the cylinder surface due to the inflow of outside air in winter .

Solution

Example of annual savings by injection machine tonnage

| standard | 100tons | 300tons | 650tons | 850tons | 1300tons | 1800tons | 2500tons | 3000tons |

|---|---|---|---|---|---|---|---|---|

| Saving power/hour | 1.0Kw | 1.6Kw | 2.5Kw | 3.2Kw | 4.2Kw | 5.5Kw | 6.2Kw | 8.0Kw |

| Annual savings | 0.66 million won | 1.6 million won | 1.65 million won | 2.11 million won | 2.77 million won | 3.63 million won | 4.09 million won | 5.28 million won |

example

These are examples of construction by Solvit Korea.

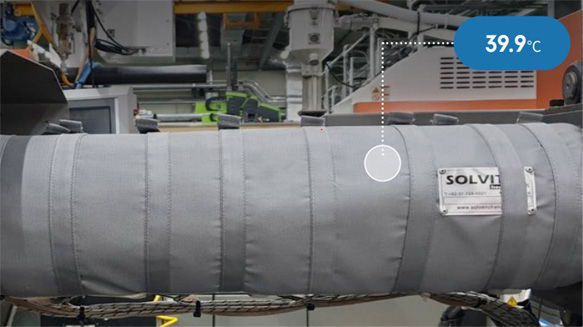

Before

Exposed to the outside before insulation increases heat generation and risk

After

It shows that the external temperature changes significantly after insulation.