Solvit Korea offers a solution

that is different from the existing insulation.

that is different from the existing insulation.

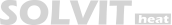

Chamber cover

Drying furnaces (chambers) are installed in various fields of

industrial sites for heat treatment or post-processing of molded products . It is a thermal insulation product that uses 10mm airgel, Velcro,

and magnets to easily attach and detach to the surface of

the drying furnace without any additional processing. Solvit Korea insulates heat exchangers and ducts that

supply hot air along with the chamber

industrial sites for heat treatment or post-processing of molded products . It is a thermal insulation product that uses 10mm airgel, Velcro,

and magnets to easily attach and detach to the surface of

the drying furnace without any additional processing. Solvit Korea insulates heat exchangers and ducts that

supply hot air along with the chamber

compare

Comparing other companies' products

| Division | Other products | Korea Solvit |

|---|---|---|

| Open type structure | Cannot be manufactured with tin casing | Production possible |

| Installation time | It takes a long time to remove and reinstall the existing insulation | 5 minutes |

| Dissipation temperature | The temperature outside the chamber is exposed as it is | 35℃ or less |

| Heat loss (Loss) | Improvement × | Improvement ○ |

Features

Features

BASICS OF DRYING FURNACE (CHAMBER)

There are two scopes for chamber insulation, depending on the method of supplying heat.

- When heating in the chamber directly with an electric heater → Only the chamber is insulated

- When supplying through heat exchange → Insulate not only the chamber but also the heat exchanger and duct

GENERAL SITUATION OF INSULATION OF DRYING FURNACE (CHAMBER)

Problems and the need for insulation

Basically enough insulation is provided inside the wall when making the chamber, but in most sites,

the need for insulation is felt due to the high surface temperature of the chamber .

Reason

This is because , regardless of the insulation installed inside the wall, the inner wall and the outer wall are connected by iron, so internal heat must be conducted to the outside through this .

CHAMBER INSULATION METHOD OF SOLVIT KOREA

- Airgel 5~10㎜ applied, insulated in detachable form

- Detachable-Easy installation and disassembly using Velcro and magnet.

- Advantages-You can easily walk and re-apply at any time. Installation time required 5 minutes

problem

Conventional method to insulate the drying furnace (chamber)

Insulation is

covered like a blanket on the top surface

Temporary, one-time

A method of installing a wall between the chamber wall and the work space

Eventually, the air circulates and

raises the workplace temperature.

A method of additionally installing a separate steel structure outside the chamber

It is sturdy and looks good, but

must be demolished when remodeling or repairing the chamber.

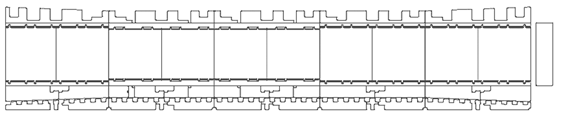

example

These are examples of construction by Solvit Korea.

Before

Exposed to the outside before insulation increases heat generation and risk

After

It shows that the external temperature changes significantly after insulation.